LITHARGE PLANT

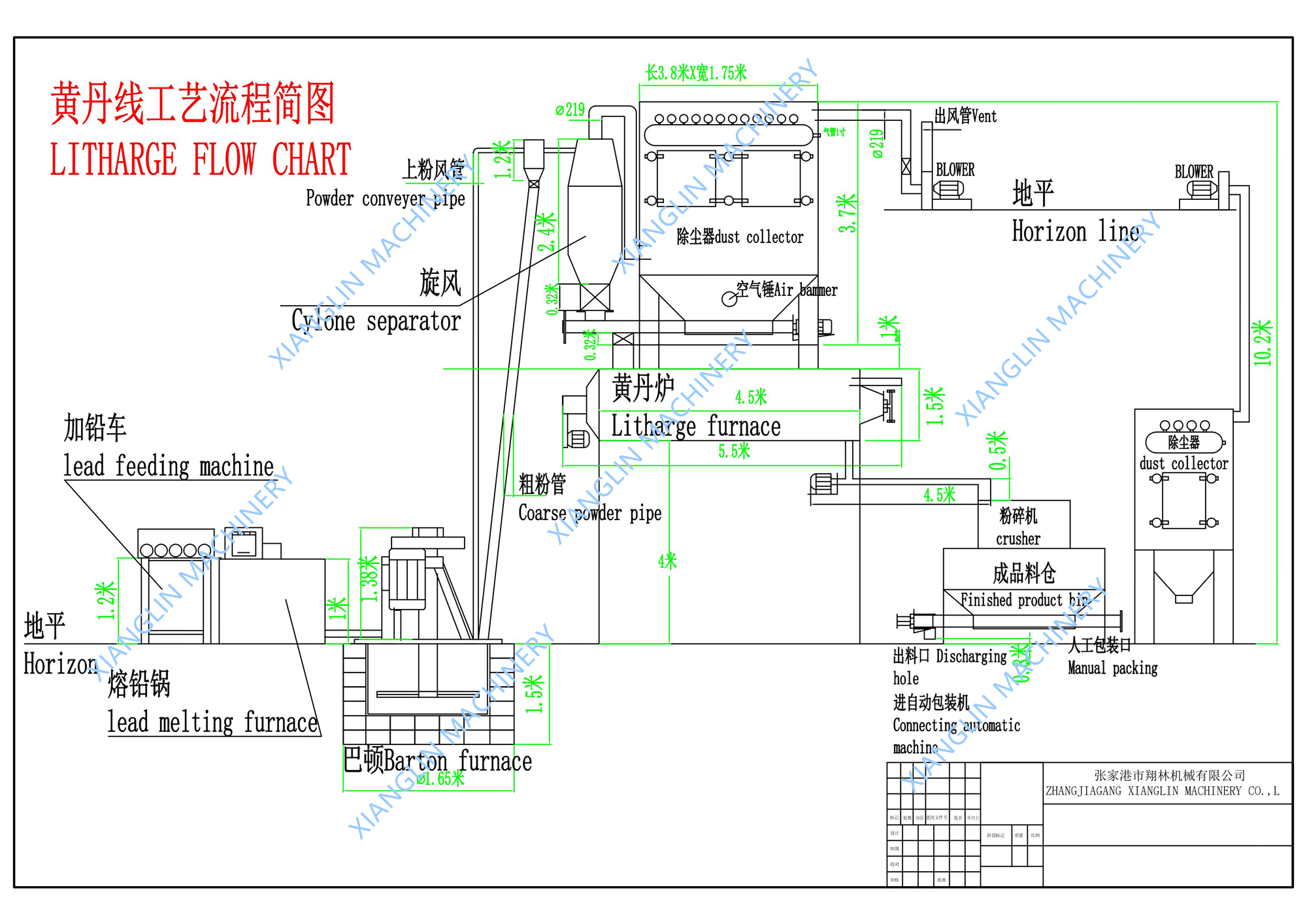

The production line makes lead ingot into lead dioxide, and then go through litharge sintering furnace second oxidized into qualified litharge powder. The production line is developed by introducing advanced concepts and technologies from the international field and combining with the requirements of modern social development. It can meet the domestic and foreign requirements of yellow lead powder, and no dust pollution.We have been improving machines in recently 20 years .The latest machine is 6th generation

| MODEL |

XLYD-5 |

XLYD-8 |

XLYD-12 |

XLYD-15 |

CUSTOMIZED OUTPUT |

| CAPACITY(T/DAY) |

5 TON |

8TON |

12TON |

15TON |

|

| MELTING POT (KW) |

12 |

15 |

18 |

21 |

|

| BARTON FURNACE (KW) |

15 |

18.5 |

22 |

30 |

|

| OXIDATION FURNACE (KW) |

45 |

60 |

65 |

75 |

|

| HEATING SYSTEM |

ELECTRICITY,GAS,DIESEL |

||||

| PRODUCT STANDARD |

≥ 99.5% |

||||

|

ITEM |

STANDARD |

| PbO % |

≥99.5 |

| FREE Pb % |

≤0.05 |

| PbO2 % |

≤0.03 |

| Insoluble substance in Nitric acid % |

≤0.1 |

| Moisture % |

≤0.2 |

| Fe2O3 % |

≤0.002 |

| CuO % |

≤0.001 |

| residue 180 mesh % |

≤0.1 |

Write your message here and send it to us