RED LEAD PLANT

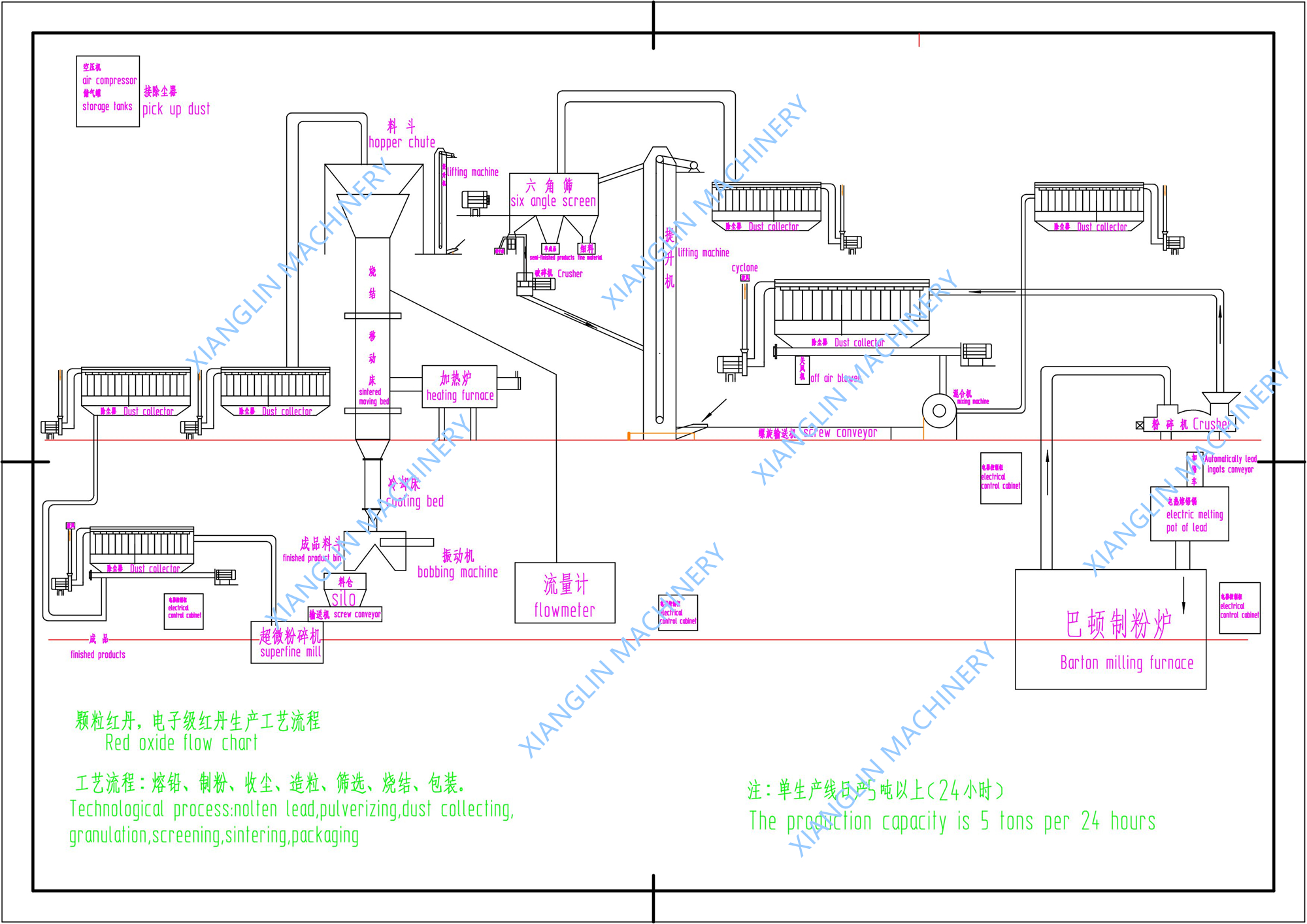

The production line adopts a new process: Barton furnace continuous melting and milling, granulation ,moving bed deep oxidation and rapid cooling. By moving bed calcination and moving bed rapid process, the solid particles are continuously moving downward in a dense state, avoiding the material collision and severe friction, so the crushing rate is very low. The moving bed reactor has large thermal inertia and small temperature fluctuation, which meets the requirement of reaction temperature. The residence time of the material in the moving bed is longer and the residence time is more uniform, and the longer time required for the reaction can be guaranteed. The reverse heat exchange between the material and the hot smoke can control the temperature of the exhaust gas ,which can use heat energy efficiently. The material moves gradually from the low temperature to the high temperature in the bed, and then gradually moves towards the low temperature, avoiding the generation of lead vapor. The standard of final product red lead is at least 97% purity .We have been improving machines in recently 20 years .The latest machine is 6th generation.

| MODEL |

XLHD-6 |

XLHD-8 |

XLHD-10 |

CUSTOMIZED OUTPUT |

| CAPACITY(T/DAY) |

5-6T |

7-8T |

9-10T |

|

| INSTALLATION POWER (KW) |

290 |

326 |

410 |

|

| ACTUAL POWER (KW) |

178 |

200 |

260 |

|

| HEATING SYSTEM |

ELECTRICITY,GAS,DIESEL |

|||

| PRODUCT STANDARD |

≥ 97% |

|||

THE STANDARD OF RED LEAD

| ITEM | STANDARD % |

| PbO2 | ≥33.9% |

| Pb3O4 | ≥97% |

| Insoluble substance in Nitric acid % | ≤0.1% |

| 105°C Volatile matter | ≤0.2% |

| Residue (38.5μm) | ≤0.75% |

| Fe2O3 | ≤0.002% |

| CuO | ≤0.001% |

| Bi | ≤0.003% |